Have I studied my business enough to understand customer demand, sales cycles, and seasonal fluctuations?ĭo I have an efficient system to get orders to customers on time?

Consider these questions to find out if it's the system for you:Ĭan I get my products out for sale in a brief period?ĭo I have a trustworthy relationship with my suppliers? Are they efficient and reliable all the time? The Just-in-Time inventory management methodology requires you to be agile and handle a production cycle much shorter than you might be used to. Is JIT Inventory Management for your business? If that sounds like your business, you are a good candidate for this strategy since it will help you lower the costs of daily operations and create a more streamlined process. Examples of booming JIT inventory industries are retailers, restaurants, publishing, tech manufacturing, and automobile manufacturing.Īs a small business owner, having regular sales and keeping an eye on cash flow are very important. This system enhances cash flow and reduces the capital you need to run your business. The JIT inventory system does work for everyone, small businesses and major corporations alike. What sort of businesses can benefit from JIT? Tesla is a fantastic example of how keeping inventory low doesn't mean you get to be less successful. Additionally, customers get a chance to ask for customization since they have to wait to get their vehicle anyways, a premium feature they might not have chosen if they could have gotten a car straight out of stock. This minimizes the amount of capital and risk from excess inventory. Tesla follows a just-in-time manufacturing approach, ensuring that parts and components are delivered to the assembly line only when required.

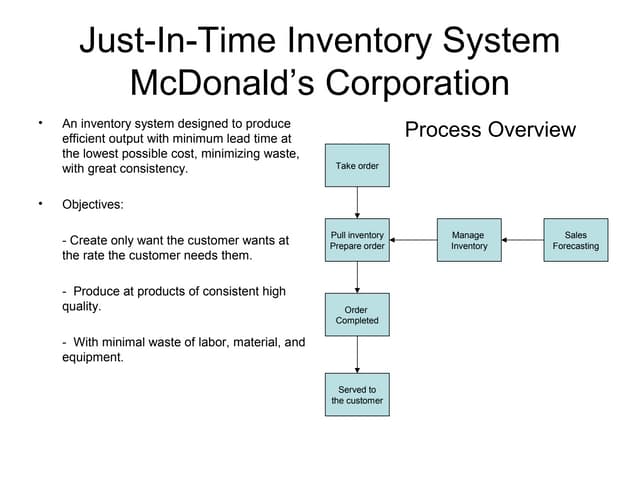

Why is that? They take complete ownership of their supply chain and even reject the traditional dealer sales model from a franchise style. Tesla is one of the world's most minor car manufacturers. For example, a natural disaster or running out of inventory if you don't track sales accurately, and perhaps even higher spending on inventory sales if more minor, more frequent orders cost more. The disadvantages include supply chain disruptions that are beyond your control. Your potential issues depend more on your business, but it's still important to consider them. If you know you get a lot of orders around Christmas time, for example, you can prepare your inventory accordingly for the surge of customer demand during those dates. When you only get what you need as you need it, you're saving a lot of money and space to use for different areas of your business.Īdditionally, you can adapt the system seasonally as you need since it creates a lot of flexibility. Benefits of JIT Inventory Managementįor small businesses, the benefits include reducing waste, minimizing storage costs, freeing physical space, and creating available cash for other expenses. For the JIT manufacturing system to succeed, companies must have steady production, a glitch-free work system, and reliable suppliers. This system reduces storage costs, saving on unwanted inventory issues since you only order what you need when you have received an order. With JIT, you decrease inventory and increase efficiency by receiving materials as you need. For this method to be successful, business owners must prepare to track and forecast consumer demand and navigate the supply chain swiftly. Instead, it will be making frequent orders to limit your inventory to what you know you will sell. This system can be handy since you only order a few materials/items. The goal is to achieve high-volume production while reducing inventory, saving space and waste, and improving cash flow. In other words, JIT inventory ensures enough stock to produce what is required when needed. With this system, you can schedule products and materials to arrive as they are needed to fulfill your orders. The Just-in-Time (JIT) inventory system allows businesses to control their upfront inventory costs more dynamically. All manufacturing or service system components, particularly people, are interconnected in JIT. JIT is a type of lean management process. What is Just-in-Time (JIT) inventory management?

In this article, we will go through everything you need to know so you can decide whether Just-in-time inventory is suitable for your business.

But what is JIT? And how does it help businesses? With increased competition and pressure to increase profits, many companies have adopted this strategy to boost their bottom line - which can be problematic when supply chains halt. If you are looking for better ways to manage your business inventory, you've likely come across Just-In-Time (JIT) inventory management, also known as Just-in-time manufacturing.

0 kommentar(er)

0 kommentar(er)